FLEXIBLE

Converting subsea

coal beds into TNZ gas,

fuels and energy

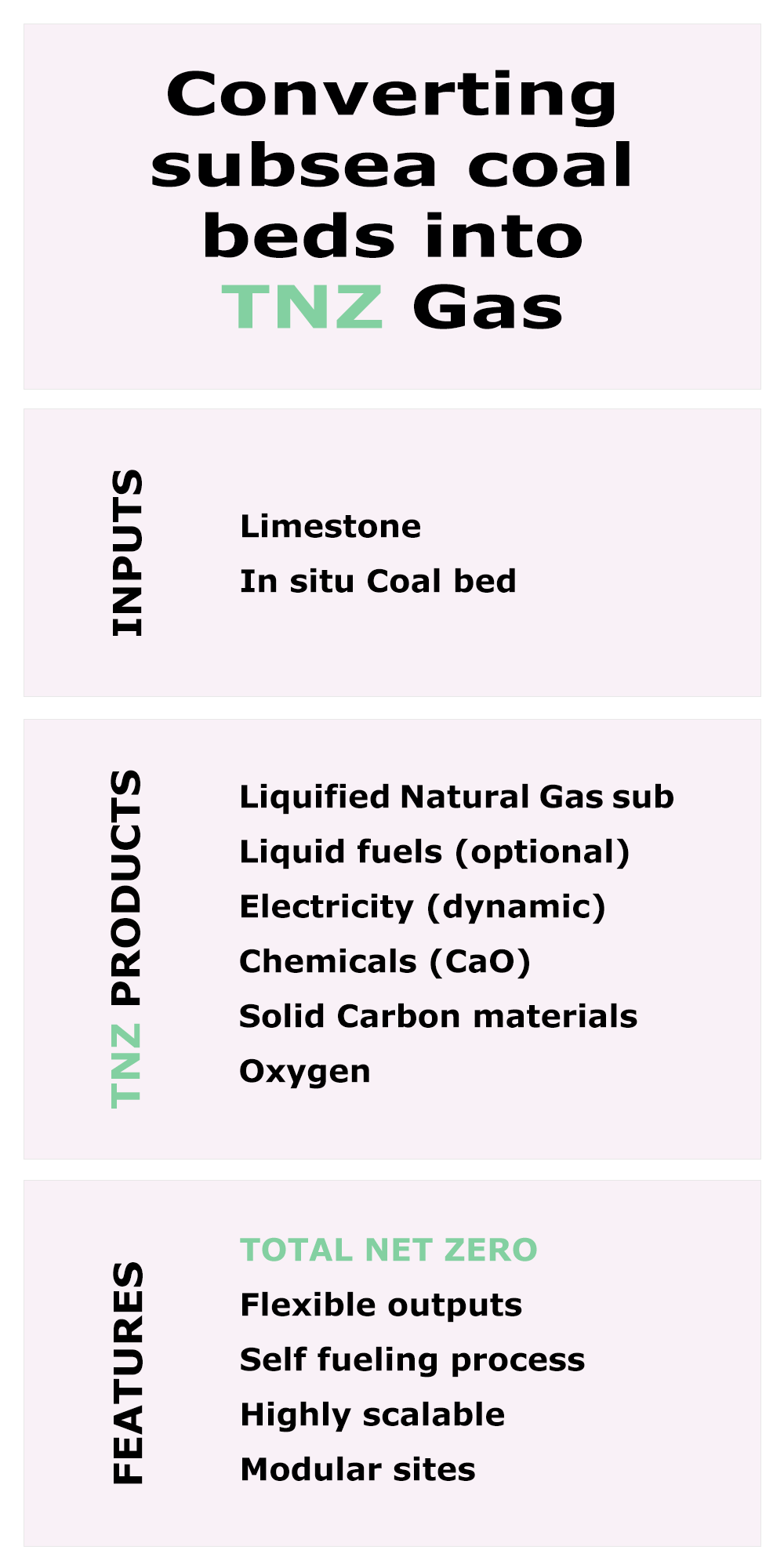

Processing underground coal in situ by pyrolysis with hot CO2 is a highly flexible process due to the multitude of final products that can be produced. The sum of the emissions from the fuel products are totally balanced by the absorptions from the CaO chemical products, thereby making this whole process TRUE NET ZERO.

Converting coal beds in situ

By converting coal beds where they lie, the coal never has to be mined, brought to the surface or touched by human hand. Instead the coal is processed remotely from the surface using advanced drilling methods which can place hot CO2 directly into the coal seam where it is batch processed to produce syngas which is piped off direct to the surface and then cleaned to produce

This remote coal bed processing means that coal resources that have been hard to reach, such as those under the North Sea, become relatively easy to access and turn into valuable fuel.

Scaleable, Modular, Flexible

When multiple coal fields are in close regions, the secondary process of turning the syngas into liquid fuels or electricity can be achieved centrally to minimise infrastructure and maximise profitability. By having the option to produce a wide range of final products, it makes this flexibility to meet instant market demands.

Self Fueling

The limestone kiln is used to produce both the hot CO2 and CaO. In this process that kiln is heated by electricity produced from the process which makes the system 'self fueling' after the initial startup.